-

All Quality Sewing Offerings

Quilters Select Free Fuse Powder

Regular price $21.99Sale price $21.99 Regular priceUnit price per$26.9919% offSale -

All Quality Sewing Offerings

Quilters Select Free Fuse Powder Refill

Regular price $13.99Sale price $13.99 Regular priceUnit price per$16.9918% offSale -

All Quality Sewing Offerings

ByAnnie's Double Sided Basting Tape 1/8in x 21-4/5yds

Regular price $7.95Sale price $7.95 Regular priceUnit price per -

All Quality Sewing Offerings

Floriani Stabilizer Perfect Stick Cutaway 15" x 10yds

Regular price $53.99Sale price $53.99 Regular priceUnit price per$76.9930% offSale -

All Quality Sewing Offerings

Clover Wonder Fuse Fusible Web 18in x 3yds

Regular price $23.50Sale price $23.50 Regular priceUnit price per -

All Quality Sewing Offerings

Floriani Stabilizer Wet N Gone

Regular price From $27.49Sale price From $27.49 Regular priceUnit price per$38.9929% offSale -

All Quality Sewing Offerings

Steam A Seam 2 - 1/2in x 20yds

Regular price $4.99Sale price $4.99 Regular priceUnit price per -

All Quality Sewing Offerings

Floriani Stabilizer Power Mesh - Natural

Regular price From $27.99Sale price From $27.99 Regular priceUnit price per$39.9930% offSale -

All Quality Sewing Offerings

1.5in White Stabilizer Caps 2 Pack

Regular price $2.49Sale price $2.49 Regular priceUnit price per -

All Quality Sewing Offerings

Floriani Stabilizer Stitch N Wash - Fusible

Regular price From $24.49Sale price From $24.49 Regular priceUnit price per$34.9930% offSale -

All Quality Sewing Offerings

Floriani Water Soluble Topping Stabilizer - 15" x 10 Yards

Regular price $20.99Sale price $20.99 Regular priceUnit price per$29.9930% offSale -

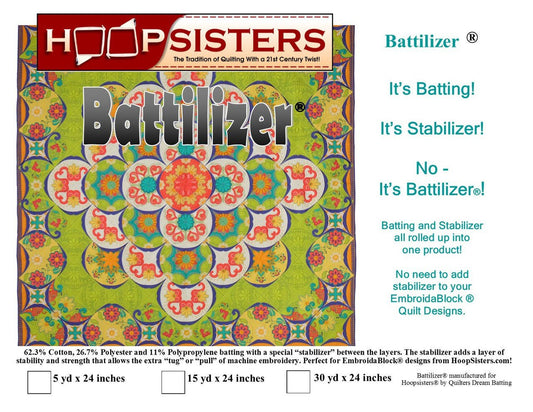

All Quality Sewing Offerings

Regular price From $33.99Sale price From $33.99 Regular priceUnit price per -

All Quality Sewing Offerings

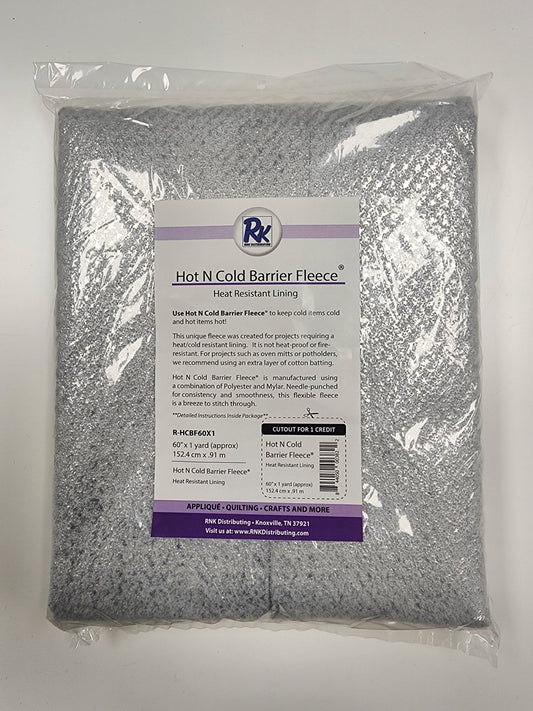

Floriani Hot N Cold Barrier Fleece

Regular price $14.99Sale price $14.99 Regular priceUnit price per -

All Quality Sewing Offerings

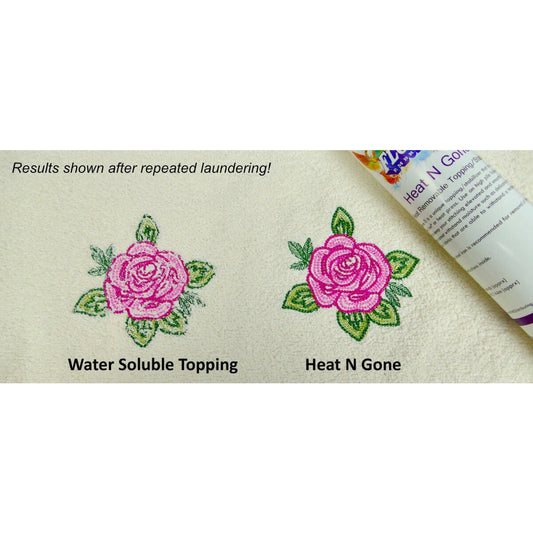

Floriani Stabilizer Heat N Gone Topping

Regular price From $11.99Sale price From $11.99 Regular priceUnit price per$16.9929% offSale -

All Quality Sewing Offerings

Regular price $14.99Sale price $14.99 Regular priceUnit price per -

All Quality Sewing Offerings

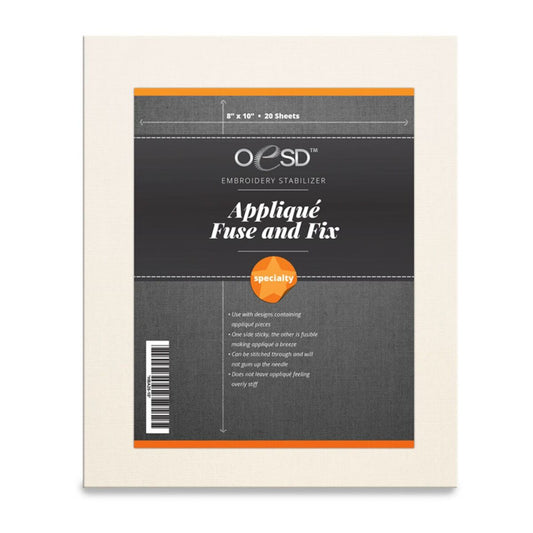

OESD Applique Fuse and Fix Stabilizer Sheets - 20 Pack

Regular price $19.99Sale price $19.99 Regular priceUnit price per

FAQs

What is embroidery stabilizer, and why is it important?

Embroidery stabilizer is a material used to support fabric during embroidery. It prevents stretching, puckering, or distortion, ensuring clean and professional-looking stitches. Using the right stabilizer is essential for achieving the best embroidery results.

What are the different types of stabilizers for embroidery?

Common types of embroidery stabilizers include:

- Tear-Away Stabilizer: Easy to remove, ideal for stable fabrics.

- Cut-Away Stabilizer: Provides long-term support for stretch fabrics.

- Water-Soluble Stabilizer: Dissolves in water, great for sheer or delicate fabrics.

- Fusible Stabilizer: Iron-on stabilizer for fabrics that need extra firmness.

What is the purpose of embroidery backing?

Embroidery backing, another term for stabilizer, adds support to fabric during embroidery. It helps maintain the fabric's shape and prevents distortion, ensuring smooth, professional-quality embroidery designs.

How do I choose the right stabilizer for my project?

To choose the right stabilizer for embroidery, consider:

- Fabric type: Use cut-away for stretchy fabrics and tear-away for stable ones.

- Design complexity: Dense designs may need heavier stabilizers.

- Project type: Water-soluble stabilizers work well for lace or sheer materials.

Can I use stabilizer on stretchy fabrics?

Yes, for stretchy fabrics, use a cut-away stabilizer. It provides long-lasting support and prevents the fabric from stretching out of shape during and after embroidery.

How do I remove embroidery stabilizer after stitching?

Removing embroidery stabilizer depends on the type:

- Tear-Away Stabilizer: Gently tear away excess material after stitching.

- Cut-Away Stabilizer: Trim the excess stabilizer close to the embroidery design.

- Water-Soluble Stabilizer: Rinse with water until the stabilizer dissolves completely.